Laser Micromachining Solutions

Markets

Medical Device Manufacturing

Laser Processes and systems for the manufacturing of smaller, precise, innovative, reliable and cost-effective medical devices. We will bring you our laser expertise to develop products for tomorrow.

See moreElectronics and Semiconductors

From front end to back end, packaging, interconnection, and assembly; our laser systems are common tools in the semiconductor and electronics manufacturing environment.

See moreWatch and Jewellery Industry

Fine Mechanics has always been at the heart of the watch making industry. Laser and related processes are the most flexible tools to express your imagination.

See moreScience and R&D

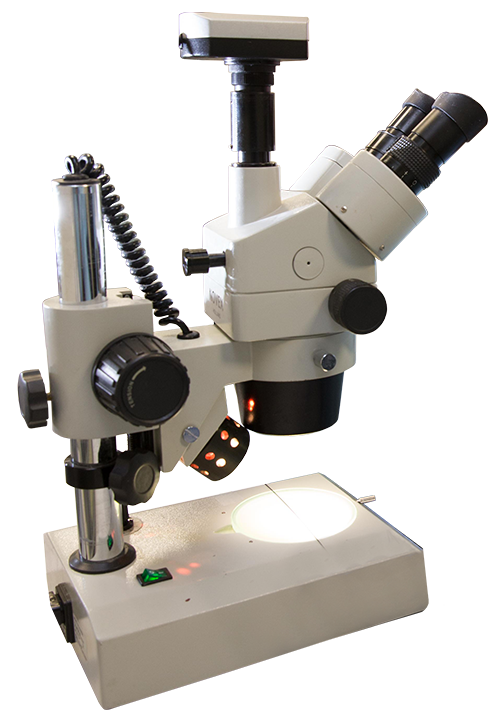

Whatever your research area, let us help you to test & implement laser processing amongst other techniques. We design and supply innovative laser tools to customers who are developing breakthrough applications in support of society’s challenges.

See moreApplicationsApplications

Laser Micro Drilling and Cutting

Laser drilling and cutting refer to the use of a laser source to create a “deep” feature on a sample.

Read more

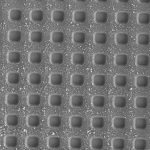

Laser Patterning

Laser patterning describes the use of laser to create a pattern onto a surface flat or shaped.

Read more

Laser Surface Treatment

Laser surface treatment describes the use of laser to create specific surface functions with smal, geometrically defined and high resolution structures. Can be masked or Maskless.

Read more

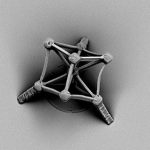

Laser Structuring

Laser structuring refers to the fabrication of 3D features such as channels, ripples, grooves and holes on the sample.

Read more

Laser Wire Stripping

Laser Wire stripping describes the use of laser to remove wire insulation without damage to the wires underneath.

Read more

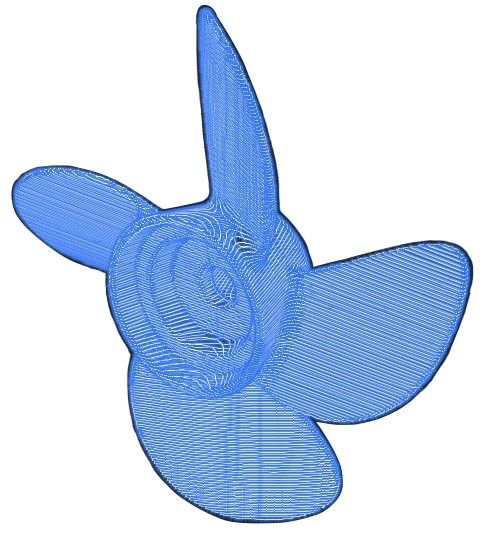

Laser Additive Manufacturing

Laser Additive Manufacturing describes the use of laser to synthesize a 3D object in which successive layer of material are formed Under computer control to create an object.

Read more

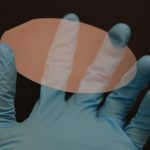

Laser Lift Off (LLO) Debonding

Laser Lift Off (LLO) refers to a process where thin layers are separated from a substrate by use of a laser beam. The main requirement for a successful LLO is only that the substrate be transparent to the working wavelength, and the target layer be opaque.

Read moreProductsProducts

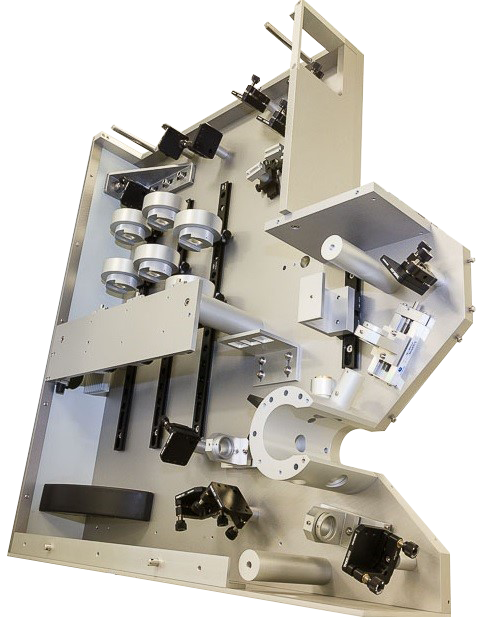

Made to Measure SYSTEMS

An important part of Optec’s strategy is in industrial machines designed and built to specific customer production requirements. It is important to understand that these are in no way prototype machines, but rather assemblies of tried and trusted components in a specific architecture optimized to best meet specific customer requirements, performance targets and local constraints.

About Optec

Optec Laser Systems is a world class supplier of laser micromachining systems and services cumulating over 100 years of laser expertise.

We operate from our 1250 m² purpose build factory in Frameries, Belgium. We have in house laboratories equipped with the latest Optec laser Tools. Our new 100m² ISO7 clean room is designed to conduct Factory Acceptance Test, Training and to offer process development as well batch and pilot production.

More about usLatest News

Technote “Excimer” #17: Excimer Lasers for Machining Optical Components

Using the the facts of depth control & ability to generate optically smooth surfaces, shows how various process strategies can be employed to create miniatu

Technote “Excimer” #16: Process Strategies for Excimer Laser Patterning

Examines the different strategies,- S&R, OTF, MS, OCM, & SCR.,- for 2D excimer patterning, in which different mask options are combined with synchronize