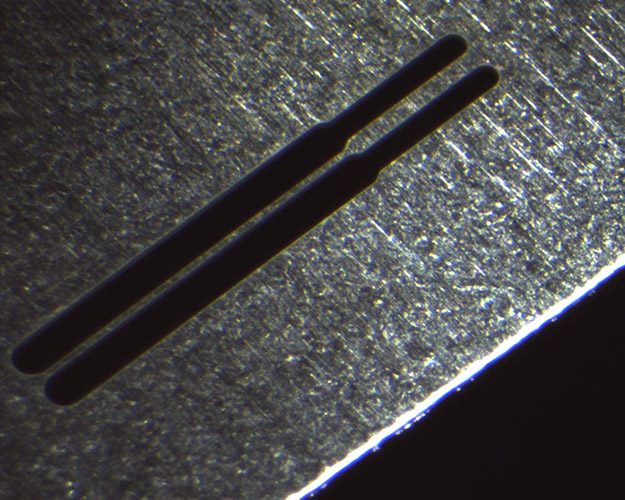

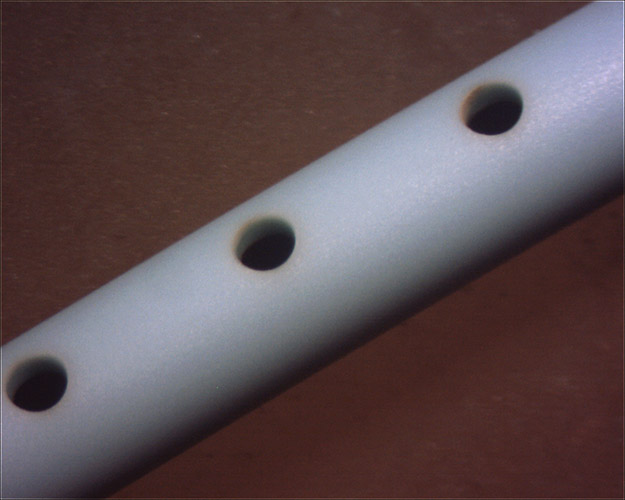

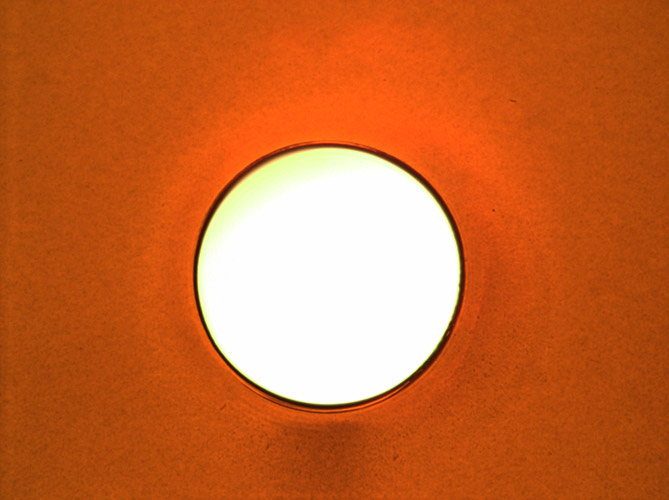

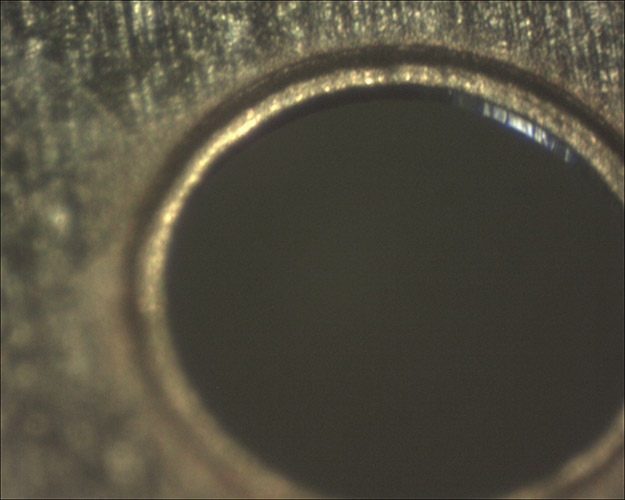

Laser Micro Drilling and Cutting

Laser drilling and cutting refers to the use of a laser source (e.g. excimer, ultrashort pulse femtosecond, fiber, diode pumped solid-state YAG) to create “deep” features on a sample, from blind holes and through holes to through cuts. The quality of the cut depends on many factors and can be gauged via different parameters including the absence of burrs on the edges, the heat affected zone (HAZ), debris, smoothness of the walls and a uniform bottom surface that has no apparent structure to it.

Optec Laser Systems specializes in A-thermal processing down to a couple of micrometers on a wide range of materials including metals, polymers, glass, ceramics, etc. We utilize proprietary technologies that yield holes and cuts with straight sides or with controlled taper characterized by their smooth walls, burr free edges and little to no HAZ or debris. Our “made-to-measure” systems are engineered with the client’s needs and priorities in mind to provide the best tool for the tasks at hand.