Engineered for miniaturization

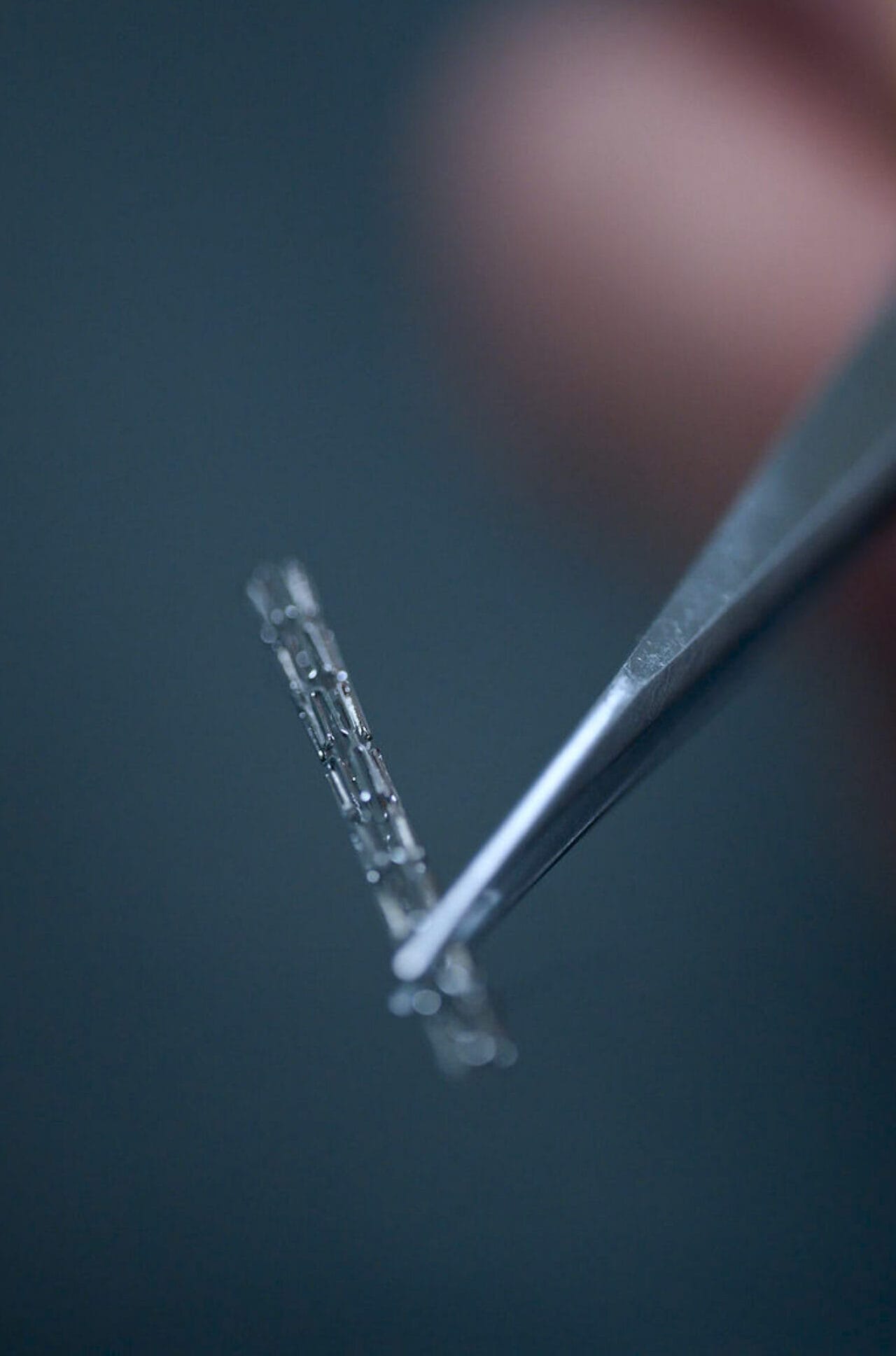

In MedTech, less is more – smaller diameters, thinner walls, tighter tolerances. Whether it is micro tubes for stents and catheters or miniature surgical components, today’s medical manufacturers face growing pressure to reduce invasiveness, accelerate time to market, and guarantee product safety. LASEA’s systems are built for that reality.

From DXF to device

Automated workflows from CAD to finished part — with fewer manual steps and less post-processing.

Minimal waste, maximum care

Process fragile and precious materials like Pt and Ptlr with minimal scrap and burr-free results.

Cleanroom-ready from the start

Sealed systems, fire-safe dust extraction, and wet cutting options support contamination-free manufacturing.

From far IR to deep UV

Excimer, CO₂ TEA, femtosecond: advanced technologies engineered for all MedTech applications.

Outcomes

From complexity to confidence

LASEA gives MedTech engineers the control and confidence they need to manufacture smaller, safer and smarter, all while keeping processes clean, compliant, and future-ready.

Precision microfabrication

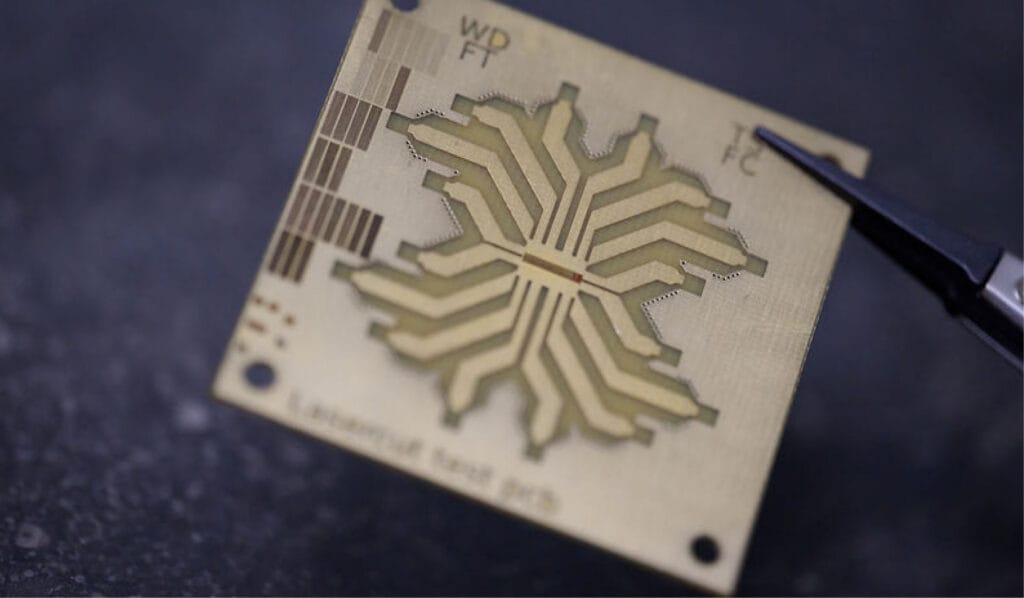

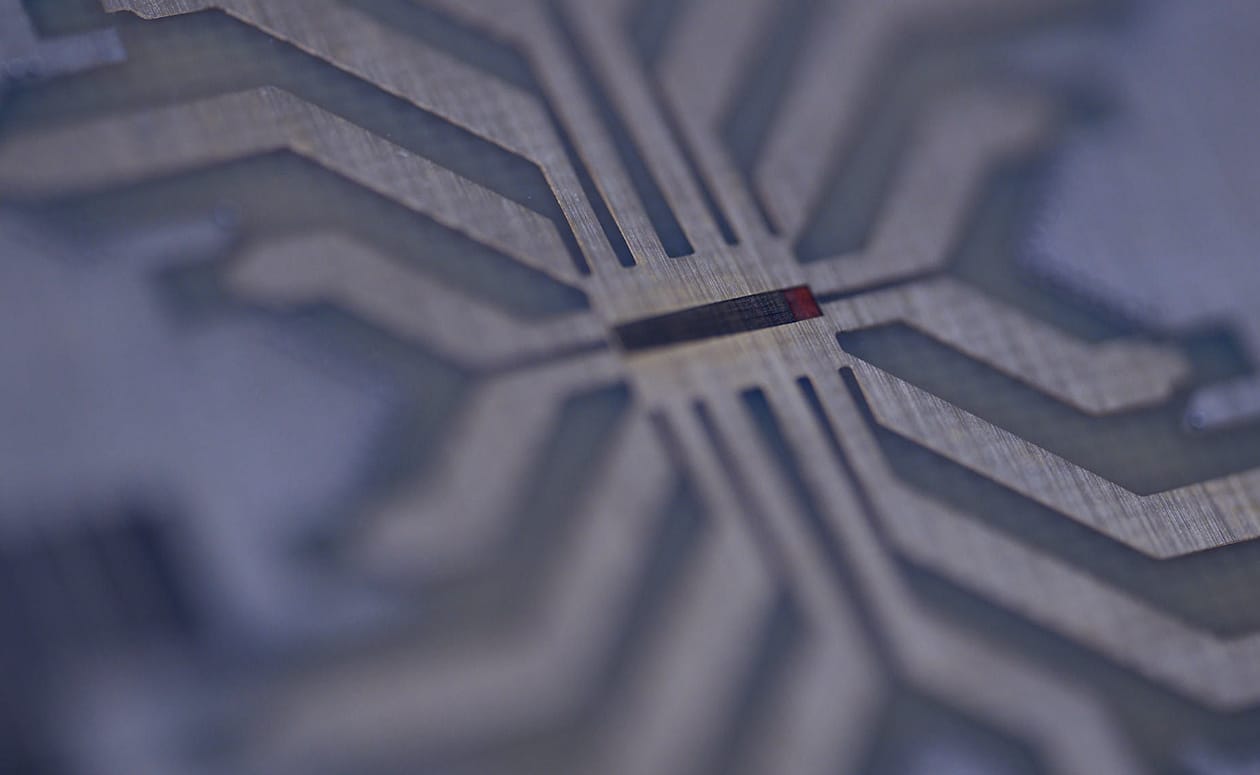

Laser cutting, chamfering, drilling, and turning – all on one machine.

Faster, simpler programming

Go quickly from complex DXF files to programmed tool paths with reduced setup time and smarter HMI tools.

Low TCO, high adaptability

Multiple optional modules and upgrade paths extend the value across device generations.

Clients in

35+ countries

Precision exactly where it’s needed.

Hybrid approaches further expand what’s possible in advanced laser processing, whether through projection masks or at the focal point.

Trusted tools for exceptional results

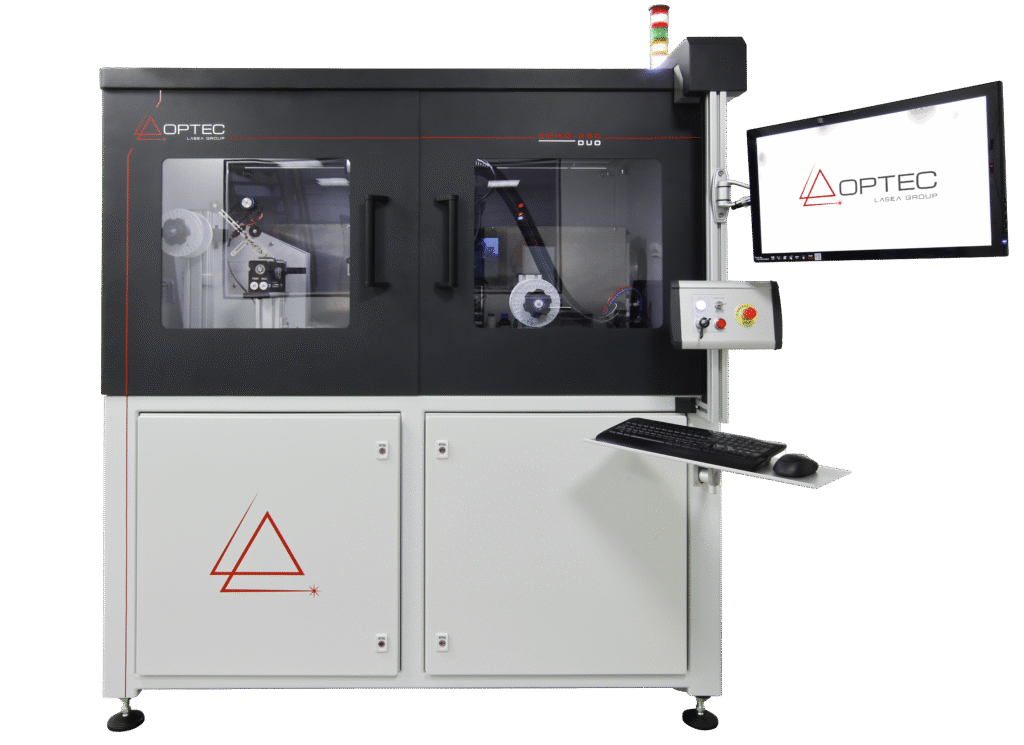

Each system is carefully configured to meet industry-specific requirements, from compact footprints and low energy consumption to integration with cleanroom environments.

What we deliver

LASEA supports MedTech innovation through advanced laser micromachining, from first prototype to regulated production.

Laser wire stripping removes insulation from ultra-fine wires with surgical precision – no contact, no blade marks, no damage. Perfect for sensitive applications in medical and electronic assemblies.

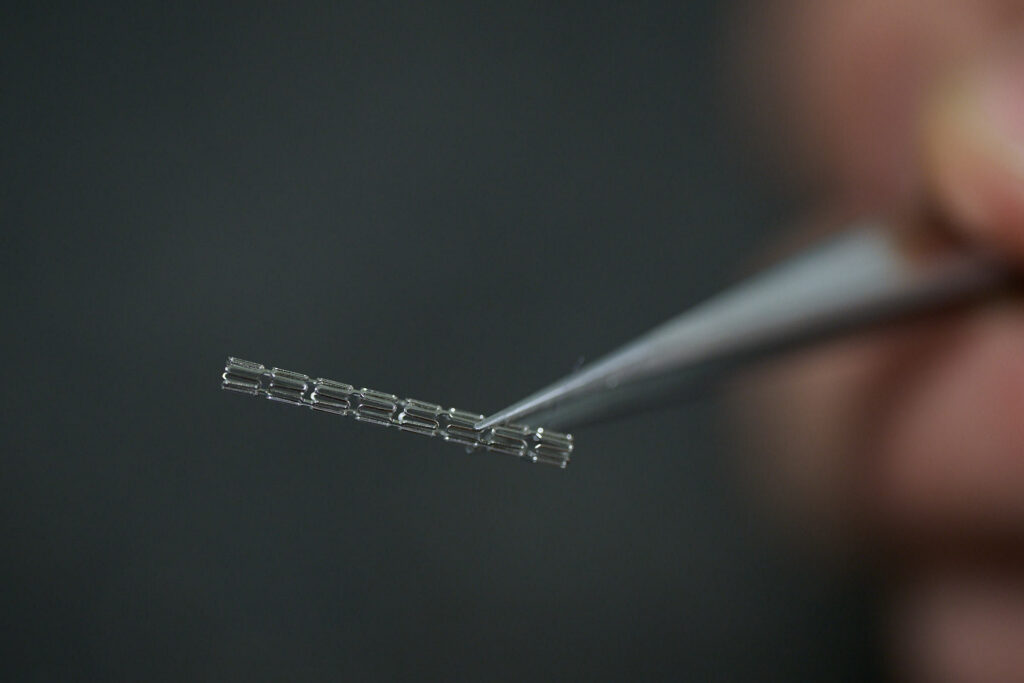

From sapphire to stainless steel, our laser cutting processes deliver burr-free, contactless results across all materials – hard, fragile, or soft. Fine edges, tight tolerances, and complex geometries come standard.

From injectors to microelectronic components, laser drilling delivers fast, accurate results across all materials. Clean holes, straight walls, zero contact.

From decorative detailing to industrial-grade traceability, laser engraving delivers precision and permanence without physical contact. Whether you work in luxury, medical devices, electronics, or aerospace, our engraving solutions combine sharp resolution with clean, controlled results.

Laser marking enables fast, clean, and durable inscription across a wide range of materials. Whether you need high-contrast codes, discrete internal markings, or tamper-proof branding, our systems deliver uncompromising quality – without contact, additives, or post-processing.

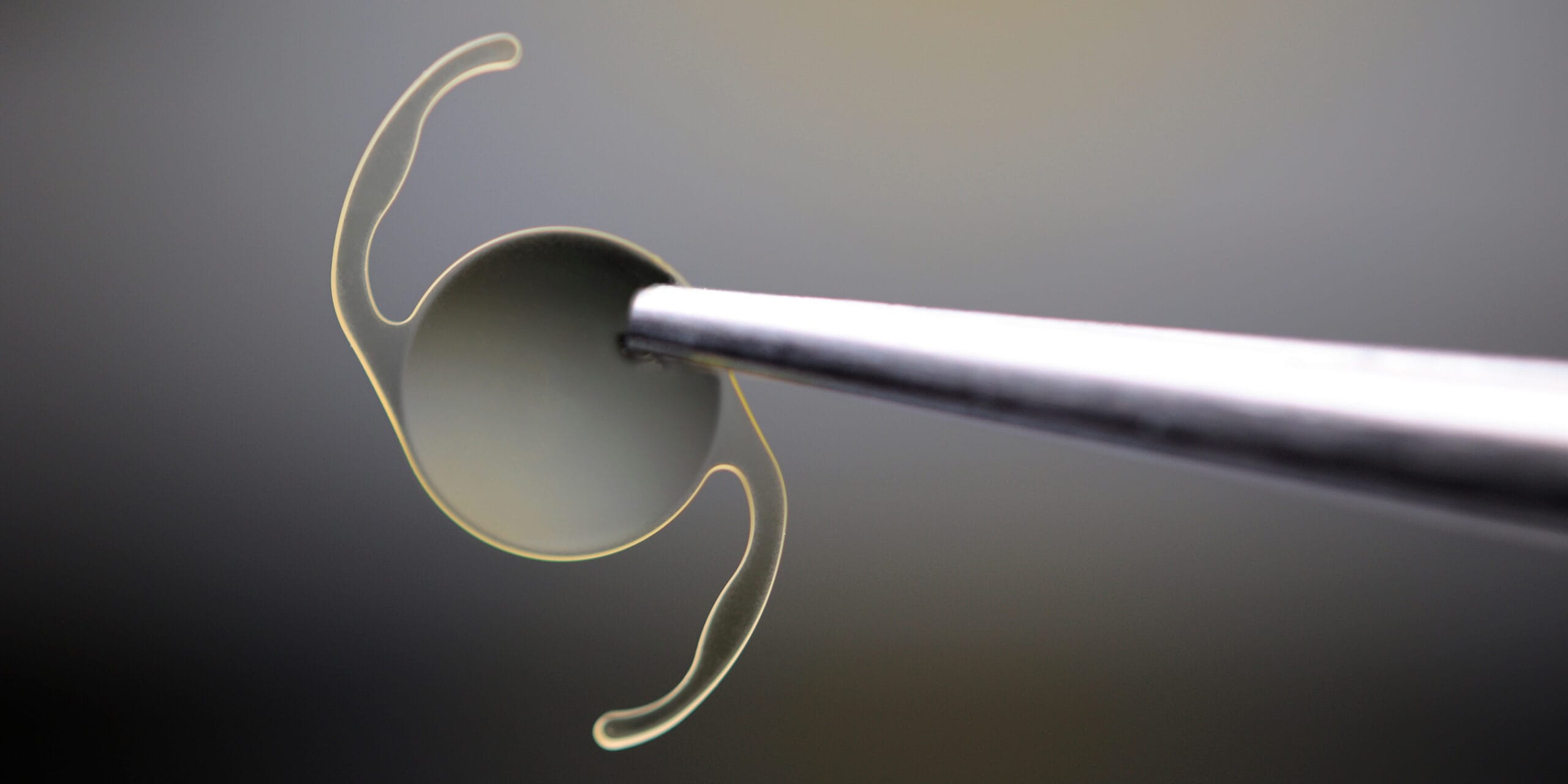

From stents and catheters to micro-needles and implants, laser micromachining enables the production of ultra-precise medical components with no physical contact or tool wear. Our laser systems are engineered to handle even the smallest tube diameters with total control and consistency.

Laser chamfering provides a non-contact, highly controlled way to shape and polish edges delivering sharp angles and immaculate finishes, especially for high-end components. Unlike mechanical methods, it avoids tool wear, stress, and inconsistency.

Laser welding delivers high-precision, non-contact joining – ideal for miniature or sensitive components across luxury, medical, electronic, and aerospace applications. From fine seams to complex material pairings, laser welding ensures clean, strong, and consistent results where traditional methods fall short.

From aesthetic finishes to functional surface engineering, laser texturing creates micro- and nano-scale patterns with speed, precision, and complete design freedom. Whether your goal is decoration, adhesion, or biomimicry, our laser solutions deliver textures that matter.

Laser turning offers tool-free precision machining for small-diameter parts – ideal for hard-to-cut materials and ultra-fine finishes. Perfect for high-end medical, electronics, and luxury components.

Scroll